Model | DMR 3-6 | DMR 3-7 | DMR 3-9 | DMR 3-13 | DMR 5-5 | DMR 5-6 | DMR 5-7 | DMR 5-9 |

Row Units | 4 Full + 2 Half | 5 Full + 2 Half | 7 Full + 2 Half | 11 Full + 2 Half | 3 Full + 2 Half | 4 Full + 2 Half | 5 Full + 2 Half | 7 Full + 2 Half |

Row Space | 40 – 50 cm | 45 – 50 cm | 45 – 50 cm | 45 – 50 cm | 70 cm | 70 cm | 70 cm | 70 cm |

Tines per Row Unit | 3 Pcs | 3 Pcs | 3 Pcs | 3 Pcs | 5 Pcs | 5 Pcs | 5 Pcs | 5 Pcs |

Required Power | 50 – 70 Hp | 50 – 70 Hp | 70 – 90 Hp | 110 – 130 Hp | 50 – 70 Hp 37 – 52 Kw | 50 – 70 Hp 37 – 52 Kw | 60 – 80 Hp | 80 – 110 Hp |

Transport Width | 300 cm | 300 cm | 400 cm | 600 cm | 300 cm | 380 cm | 430 cm | 600 cm |

Weight | 590 kg | 665 kg | 975 kg | 1500 kg | 560 kg | 640 kg | 760 kg | 1050 kg |

Fixed frame row crop cultivator is used for hoeing and chopping the weeds between cultivated corn, beet, sunflower and cotton.

Rollers are mounted with reinforced bearings.

Standard row unit.

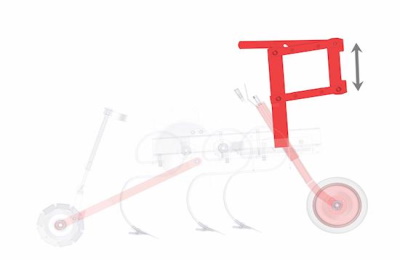

Parallel linkage is mounted on replaceable metallic bushes which has high clearance . 3 steps adjustable down pressure spring is standart.

As standartly, row units have 300 mm rubber depth adjustment wheel.

High quality spring tines made from spring steel.

Iron wheels help the machine to follow tractor perfectly. Wide dimension create perfect contact on soil and help optimum depth adjustment.

Central fertilizer wheel protect crops any damages unlike side fertilizer wheel. Moreover,it’s easy to follow wheel during working.

150X100 frame gives robustness even on big models.